The new Profometer PM8500 Corrosion

The fastest and most reliable way to map corrosion potential in reinforced concrete structures.

Contact us →

.png?width=200&height=200&name=wirless%20solutions%202%20(1).png)

Assess concrete health

The Profometer PM8500 uses a half-cell potential measurement technique to assess corrosion probability in reinforced concrete. Use it to identify and map areas with corrosion likelihood, estimate the corrosion potential of rebars, estimate concrete durability, and evaluate the effectiveness of corrosion repairs on a wide range of reinforced concrete structures, including bridges, buildings, parking structures, and other infrastructure.

Map corrosion in hard-to-reach areas

Make light work of mapping corrosion in hard-to-reach areas, such as inside concrete pipes and culverts, underneath bridges and overpasses, behind concrete walls and columns, and in congested areas with limited access. This is crucial because corrosion can occur in any part of a concrete element, leading to costly repairs or failures. By identifying areas of corrosion early on, the PM8500 and its unique wheel electrodes can reduce costs and improve the safety and durability of concrete structures.

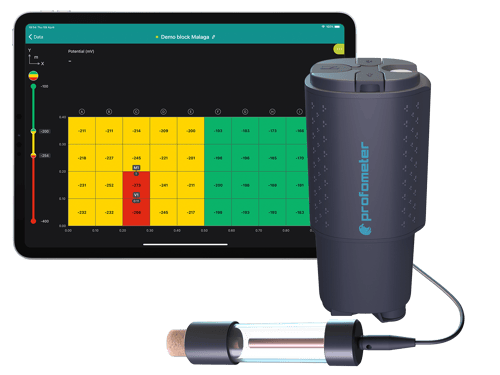

Real-time data analytics and visualization

Real-time data visualization is essential for effective concrete corrosion assessments. The PM8500, connected wirelessly to the iPad, provides you with immediate analytics of the corrosion data, enabling you to identify areas of concern as fast as possible. The software's data visualization tools, such as 2D imaging, heat maps, advanced statistics and custom gradient maps gives you a clear indication of any areas with potential corrosion. And with secure web-based data storage, you can enjoy streamlined data export and collaboration.

Profometer PM8500 Corrosion Kit

This kit is the base that can be upgraded at any time with the add-ons presented below. The kit is a complete solution that consists of a sensor and software for on-site mapping of corrosion potential, including a rod electrode to quickly scan small areas such as columns or beams.

text jump

.png?width=200&height=200&name=MicrosoftTeams-image%20(36).png)

.png?width=200&height=200&name=MicrosoftTeams-image%20(37).png)